Filtration (fluytec)

Filtration Technologies

40 years’ experience in designing and manufacturing new equipment and innovative solutions has enabled Fluytec’s participation in desalination, treatment and potabilisation projects for agricultural and human use as well as in projects for food industry water treatment, power generation and, generally, all process water treatments for industry.

All of this reflects wide know-how accumulated worldwide, based on leadership in the Spanish market. This expansion is the fruit of undertaking work supported on three basic pillars:

- Engineering that can develop any solution required for incorporation in the filtering process.

- Wide experience in all types of geographical and climatic environments and activity sectors that allows us to provide the most suitable solution for each case.

- A Quality Policy with ISO 9001, ISO 14001 and NSF 61 certifications that guarantees the suitability not only of our products but also of our working activities

A knowledge of the reality of the filtering world makes Fluytec an organization designed and conceived to contribute to improving its proposals, making it an essential collaborator beyond a simple supplier of equipment.

Fluytec Automatic Backwash filters allow continuous filtering together with a backwash process. This equipment is especially appropriate for applications in which filtering continuity is a key parameter. They are specially designed to work with sea water and ultrafiltration plants.

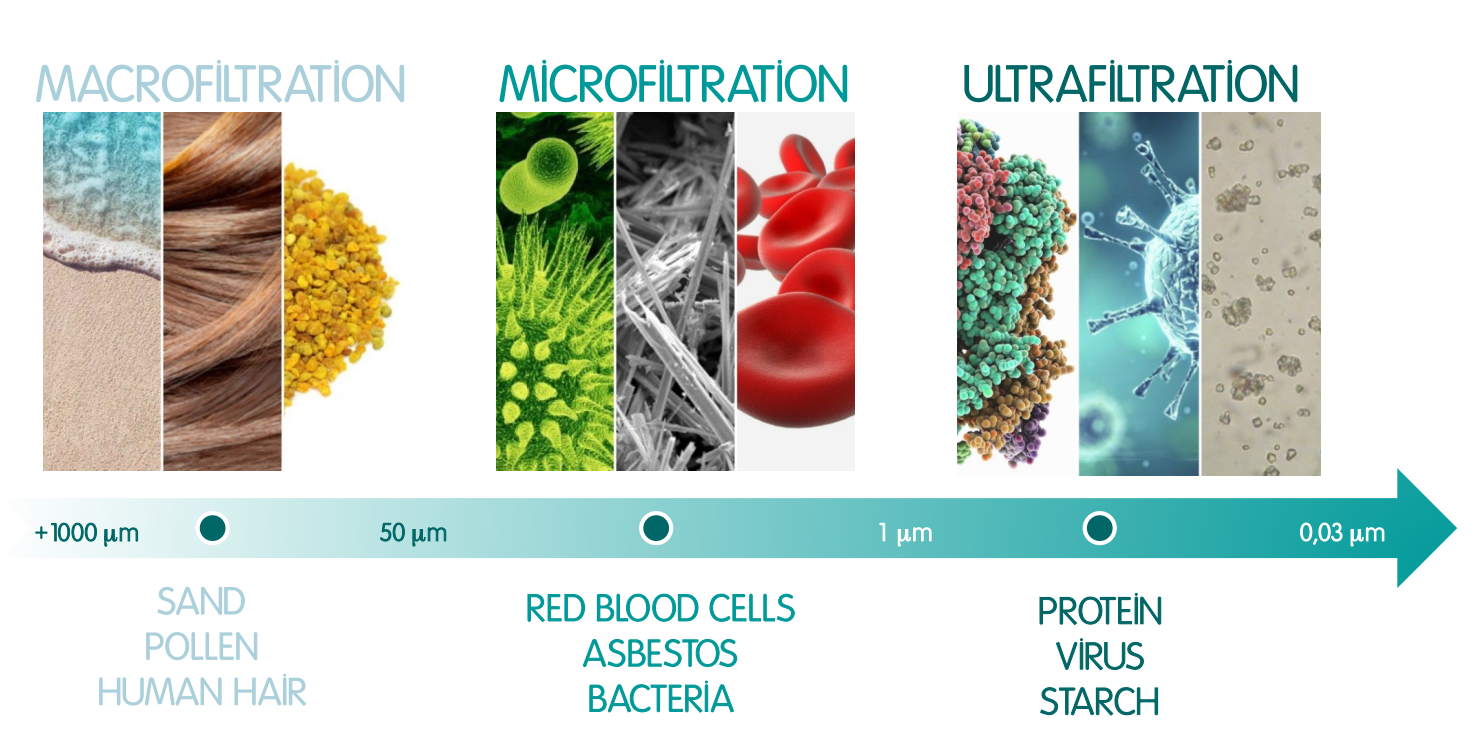

Fluytec Microfiltration Filters are especially suitable for applications in which, because of their specific

needs(high pressures/temperatures/corrosive media/High flow of the fluid to be treated).In the quest to develop heavy duty equipment for the Industry’s most demanding applications, Fluytec has combined Glass-fiber Reinforced Polyester (FRP/GRP) vessels with a Proprietary Boltless Opening. As a result, Fluytec has created a unique Quick Opening and fully NonCorrosive filter.

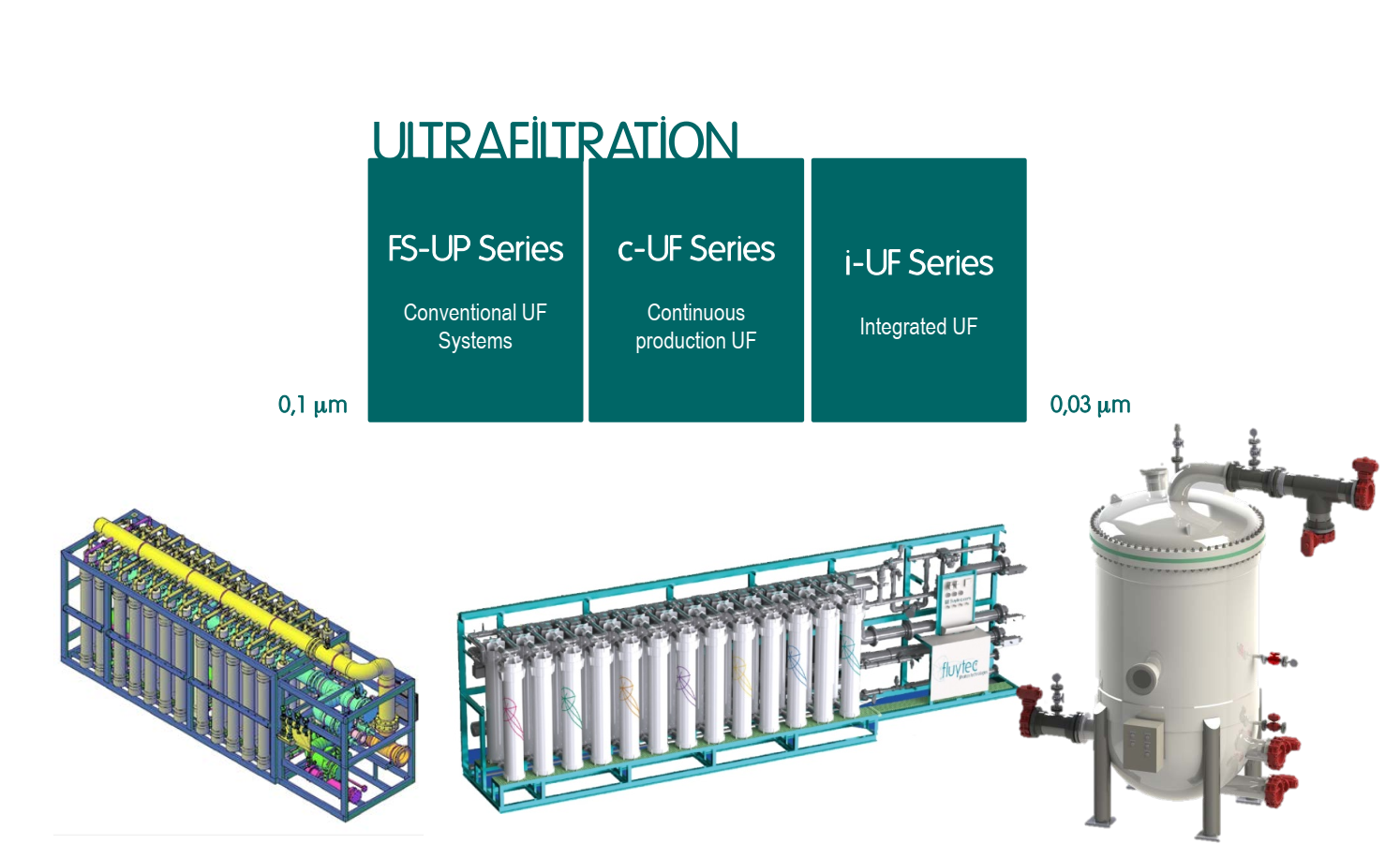

Fluytec’s Ultrafiltration Systems are based on outside-in flow configuration ultrafiltration modules, which allow for less plugging, higher solids loading, higher flow area and easy cleaning. The primary flow design is dead-end filtration which uses less energy and has a lower operating pressure than the concentrate bleed, therefore reducing operating costs. Our standard systems are designed for reliable, long term trouble free operation, with straight forward control.

Fluytec has revolved around conventional Ultrafiltration technology in order to develop a new generation of UF, which is capable of granting a constant product flow even during cleanings (Backwash, Flushing, Rinsing and Chemically Enhanced Flushing). This innovation eliminates the need for backwash pumps and blowers, buffer/ backwash tanks and transfer pumps to the process located downstream (i.e. Reverse Osmosis).

The i-UF represents the natural evolution of UF filtration, where the integration of the screening and membrane filtration in a single vessel strengthens the footprint, pressure rating and robustness benefits of vessel contained UF.

For more information, please refer to: http://www.fluytec.com/en/index.php