Dosing Pump (FWT)

Solenoid Driven Dosing Pumps

Dosing pumps or Metering pumps or Chemical Feeders belong to the family of alternating volumetric pumps. Solenoid driven dosing pump are recommended when:

- small performances are required

- there is a need for reliability and versatility due to electronic controls

FWT offers a wide range of operating modes through different series giving an overall solution to most of duties requirements.

MX series

- Small performances WALL mounting solenoid dosing pumps

Flow rates from 1,5 to 7 l/h / pressure up to 7 bar

X series

- Small / medium performances FOOT mounting solenoid dosing pumps

Flow rates from 1,5 to 22 l/h / pressure up to 20 bar

VX series

- High performances WALL mounting solenoid dosing pumps

Flow rates from 5 at 20 bar, up to 20 / 30 / 50 / 80 l/h

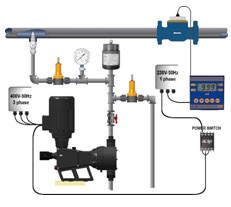

Motor Driven Dosing Pumps

Motor Driven Metering pumps belong to the family of alternating volumetric pumps. Motor dosing pumps are recommended when high performances are required.

MAIN FEATURES

- Gearbox in cast aluminium protected with Epoxy paint

- Flow rate adjustment via stroke length from 0-100% whilst in operation or at rest

- Motor/gearbox are coupled by means of flexible coupling, thus increasing transmission life

- Standard power supply: 230/400 Vac 50 Hz / 275/480 Vac 60 Hz; 3 phase,+/-10%

MOTORS CHARACTERISTICS

- Standard MULTI FREQUENCE/VOLTAGE: 230-400Vac 50Hz • 275-480Vac 60Hz / 3phase / ±10%

- Conform with IP55 protection. Isolation class F, others available upon request

- Motors are TEFC vertically mounted, B14 type, ?1400 rpm

Other power supply upon request:

- 230 Vac 1 phase 50 Hz or 230 Vac 60 Hz (*) • 110 Vac 1 phase 50 Hz or 60 Hz (*)

(*) NOTE: at 60 Hz frequency, motor speed and thus stroke rates and flow rates increase by approx. 20%

MECHANICAL ACTUATED DIAPHRAGM METERING PUMPS

Mechanical diaphragm type pumps are suitable when:

- Zero leakage is essential

- Pumped liquid contains suspended solids particles

DIAPHRAGM PUMPS

-

- Flow rates from 18 to 1000 l/h

- Pressures from 8 to 3 bar

- Standard motor 0,18 kW

- Small dimensions

PLUNGER TYPE METERING PUMPS

Piston type pumps are suitable when:

- High flow rate dosing is required

- Dosing high viscosity liquids

PLUNGER PUMPS

-

- Flow rates from 6 to 1027 l/h

- Pressures from 20 to 3 bar

- Standard motors 0,18 to 0,75 kW

- Small dimensions

PUMP ADJUSTMENT CONTROL

Constant / ON-OFF mode: knowing the amount of additive to inject, pump flow rate (injected single stroke volume) is adjusted via piston strokes length by means a knob which regulates the micrometer screw. The pump will constantly perform the dosing operation according to flow rate by the selected frequency. Connected to a Remote On/Off equipment, the pump will start and stop operations according to the external contact.

Inverter to control pump flow via remote control from external input signal 4?20 mA, upon request.

Servomotor 4÷20mA or 0?10Vdc for flow automatic control via stroke length control, upon request.

Controller to manage external contacts (e.g. water meter) synchronizing the activation time of output relay: recommended for proportional dosing (dividing mode) with motor dosing pumps.

For more information, please refer to: http://www.fwtsystems.it/