Dosing Pump (Etatron)

Solenoid Driven Dosing Pumps

Flow rate from 0,25 to 80 l/h (0,07 to 21.12 GPH) • Working pressure up to 20 bar (290 PSI) • Anti-acid plastic casing or die cast aluminum casing • Foot or wall-mounting design • Analogical & microcontroller based pumps • Pumps with integrated measures control for pH, mV, free Chlorine • Multifunction pumps, flow alarm • Manual stroke length adjustment • Proportional function to external mA signal • Solar panel dosing system

Etatron offers a wide range of operating modes through different series giving an overall solution to most of duties requirements.

eOne – eOne B

“Clever” dosing pump with power control according to the actual dosing conditions. Flow control when the pressure in the system varies, energy-saving, less heating and wear of the device, high injection frequency (up to 300 imp/min)

UNDERLOAD and OVERLOAD function that allows you to generate an alarm due to lack of liquid in the suction or the dosage blocked in the delivery

Multi-voltage power supply: 100… 250Vac (50/60 Hz). Available in all versions, analog manual, multifunction (proportional to external signals), and, in the Plus version, proportional to external signals and with a built-in measuring instrument. An enclosure for wall or base mounting.

PKX

The PKX series dosing pumps are a perfect solution for the small dosings with an exceptional relationship quality/price; the mounting bracket (included) simplifies the installation both on the wall and on the horizontal base.

MultiFlow

Analogical dosing pump with model selection and manual flow rate adjustment.

The Multiflow is an electromagnetic pump with constant flow rate. The model (max flow rate/working pressure) can be selected by the user

DLX – DLXB

The high reliability and the competitive price make the DLX series the best o er in the quality/price ratio in the dosing pump market. On the DLXB series, with a base for horizontal mounting, an adjustment system for the quantity for every single injection is available on request that allows the user to modify the quantity dosed for every single injection, varying the stroke between 20 and 100%. Available as version manual analogical, a digital manual, multi-function (proportional dosing by external signals), and with measuring instrument built-in.

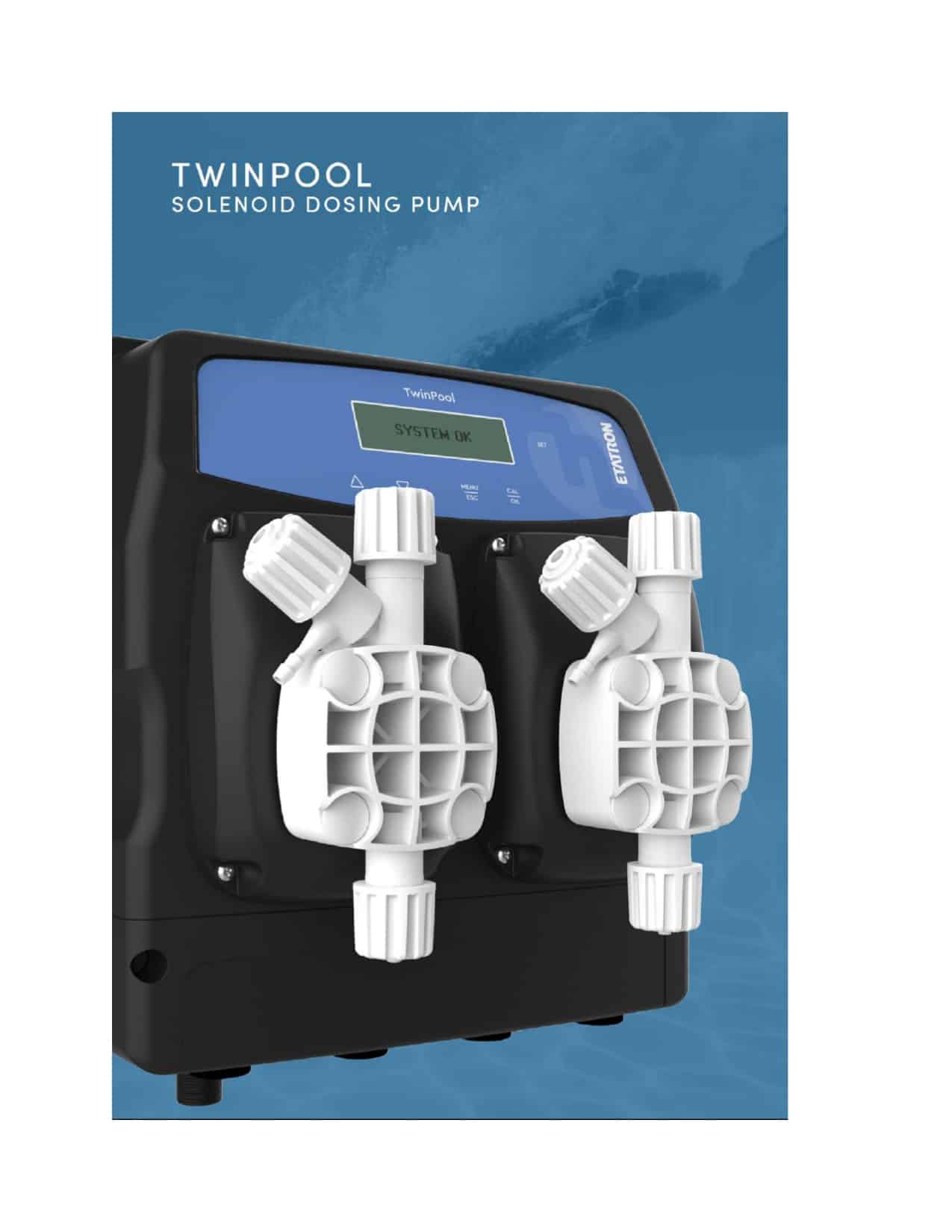

TwinPool

Regulation and dosing system for the control of two chemical parameters (pH-Rx), with ON-OFF, proportional dosage, hysteresis regulation, the delay time for the activation of the electromagnetic dosing pumps.

- overdose alarm

- level control, relay output for alarm signaling

- Three user-configurable relays, set-point (measurements + temperature) or timer

- case in antacid plastic material, graphic display, wall mounting with IP65 protection, complete with mounting kit.

Motor Driven Pumps

Piston pumps • Diaphragm pumps • Flow rate up to 7000 l/h (1765 GPH) • Working pressure up to 280 bar (4000 PSI) • Manual stroke length adjustment • Motor with integral Inverter to accept 4÷20 mA signal (15÷50 Hz) • 4÷20 mA servo motor • Pressure relief and safety valves • Pulsation dampeners

Diaphragm

Diaphragm metering pumps. The mechanism, the motor, and the dimensions of the membrane make it a product for high performance in the industrial and water treatment market.

PISTON

Plunger piston metering pumps. It is a high-performance product in the industrial and water treatment market. Above all, due to the high operating pressures at which dosing can be carried out.

Controllers

• pH, Rx (ORP), chlorine residual analyzer and conductivity meters

• Wall or panel mounted design (DIN)

• Plastic or glass electrodes

• Temperature probes, conductivity probe

• Probe holders

• Free and total chlorine probe

• Hydrogen peroxide probes

Control and Regulating Systems

Dosing pump and pH, RX (ORP) or conductivity controller built into one compact unit • Level alarm • Cooling towers controller • Multi-parameter photometric analyzer • Control units for pH; RX (ORP); free and total chlorine residual; hydrogen peroxide; peracetic acid; chlorine dioxide; temperature.

For more information, please refer to: http://www.etatronds.it/